With a vision to revolutionise forestry

AirForestry is the company with the vision to make forestry sustainable. AirForestry’s ground-breaking technology allows forests to be thinned from the air. This helps to preserve many of the forest’s values while solving some of the sustainability challenges that exist today.

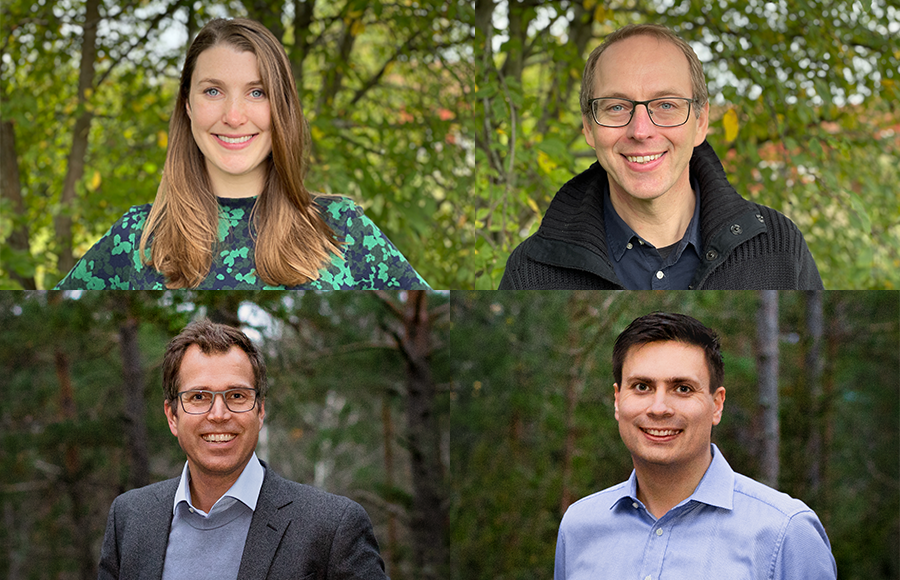

‘One of today’s big challenges is the lack of a good technology that is gentle while at the same time allowing forests to be managed sustainably. In order to make forests more productive and sustainable, promote diversity and sequester more carbon dioxide, we need a technology that delivers all these values in forests,’ explains Markus Romar, co-founder of AirForestry.

He is a trained agronomist and economist from SLU with several years’ experience of running an agriculture and nature restoration company. He was active early on at the Green innovation Park in Uppsala.

‘I met Mauritz Andersson at a networking breakfast at the Green Innovation Park, and he later became the company’s co-founder. He told me that flying a person from Stockholm to Gothenburg was as energy-efficient as taking the train. He also said that flying over objects and goods is more energy-efficient than transporting them on land. This was how the idea was born.

Developing the idea

Together, Markus and Mauritz, who has a background in electric aviation, looked at ways in which aeronautics can be used to solve larger problems, for instance in forestry. After exploring several sectors, they eventually landed in forestry.

‘We know it’s possible to fly a drone from point A to B, we know it’s possible to build larger drones, and we know it’s possible to prune trees, but doing it from the air is a different thing entirely,’ Markus says.

Markus contacted Olle Gelin, one of Sweden’s leading experts in forestry technology and traditional machinery, who is now CEO of AirForestry. Their idea was indirectly verified through him.

‘In a short space of time, the three of us turned the whole idea into a concept, which we patented and which now forms the basis for our company,’ says Markus.

AirForestry’s concept

The concept involves a high-capacity drone and a harvesting tool with a base station. In a single step you can go out, harvest a tree in just a few seconds and transport it back to the nearest road for pick-up. The drone needs a number of unique features in order to process a tree. This meant they had to build something from scratch.

‘We quickly obtained funding from SLU Holding AB in order to develop a prototype at an early stage to prove the feasibility of the idea.

The Walerud family also played an important role in AirForestry’s journey.

‘The Walerud family quickly stepped in as investors and were strongly committed to the company right from the outset. Caroline Walerud became the fourth co-founder and is now Chair of the Board.’

Green Innovation Park

According to Markus, being at the Green Innovation Park has made things much easier.

‘There’s a fantastic culture and environment there that’s brimming with innovation and new ideas. It’s given us opportunities to meet like-minded people, exchange ideas and forge our entrepreneurial journey.’

There are also various support functions available on-site that facilitate business start-ups, which reduces friction, Markus points out.

About 25 people are involved in the company today. The company has relocated to Verkstadsgatan in Boländerna, Uppsala, where it has a new aviation laboratory and a large workshop. They will also relocate their specially adapted offices there in a year’s time.

Jenny Lindblad, CMO at AirForestery, adds:

‘AirForestry has grown unusually quickly for a start-up. If we hadn’t expanded so fast we could just as well have stayed at the Green Innovation Park.

The advantages of the technology

Markus explains that AirForestry’s technology allows forestry to be planned in a completely new way.

Harvesting the trees one at a time allows you to decide how to manage the forest. For this reason, he argues, their product is much better than others available today.

‘When we thin the forest, we harvest the smaller trees to make the remaining forest more sustainable and productive and prioritise the trees with the best characteristics. We also eliminate all the damage to surrounding land and trees that heavy machines cause when creating access roads, which currently make up 20% of forest land.´

Future challenges

The next step for AirForestry is to harvest the first tree.

‘We’ve built a high-capacity flying drone. We’ve built a tree harvesting tool, and now we’re integrating all the parts together to harvest the first tree in the world. That will happen very soon,’ Markus says.

He hopes that in the future, AirForestry will be involved in solving the big challenges faced in the forestry sector, including at a global level.

‘To do that, we need to build something extremely scalable and functional that can solve the big challenges and be supplied on a large scale. We hope that’s what we’ve now done.’

‘Regarding the future, I’d like to add that we want AirForestry to be seen as the company that revolutionised forestry,’ says Jenny Lindblad, CMO, AirForestry.

Find out more at airforestry.com